The Vital importance of Maintaining Filters in machines, Equipment and Vehicles

When it comes to maintaining the optimal performance of machines, equipment, and vehicles, it is easy to overlook one of the most crucial components: filters. These small but powerful devices play an essential role in the smooth and efficient operation of a wide range of assets, from automobiles to industrial machinery and HVAC systems. In this blog, we will explore the vital importance of providing regular maintenance to filters and how this can have a significant impact on durability, efficiency, and cost savings.

Why are filters so crucial? Filters are the silent guardians of the functionality of many machines and vehicles. Their primary function is to trap unwanted particles, dust, dirt, pollen, and other contaminants that could damage internal components or reduce efficiency. Some key areas where filters are fundamental include:

Motor Vehicles: Air and oil filters are essential for maintaining engine performance and service life. A clogged air filter can reduce engine efficiency and increase fuel consumption.

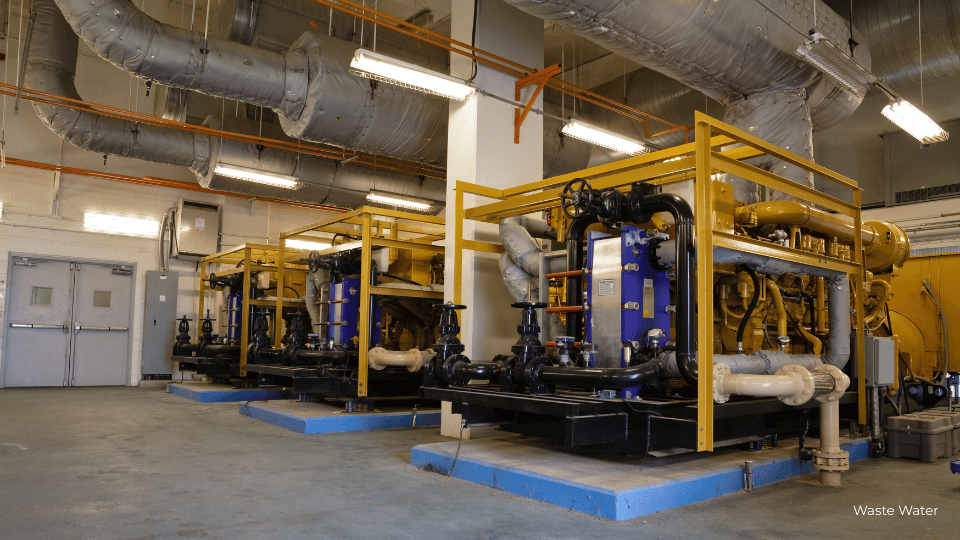

Industrial Machinery: In industrial environments, filters in ventilation systems, compressed air, and processing equipment protect both the machinery and product quality.

HVAC Systems: Filters in HVAC systems in buildings and vehicles ensure that the air is clean and healthy to breathe. They also prevent the accumulation of dirt on coils and ducts.

Benefits of Regular Filter Maintenance

Better Performance: Clean filters allow for unobstructed air and liquid flow, which translates into more efficient performance and greater power.

Durability: By reducing the workload on internal components, filter maintenance can prolong the service life of equipment and vehicles.

Cost Savings: Proper filter maintenance can prevent costly repairs and reduce fuel consumption in vehicles.

Air Quality: In HVAC applications, good filter maintenance ensures cleaner and healthier indoor air.