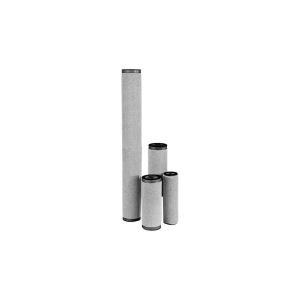

- Swirl Flow Design — Filtration Systems’ patented Swirl Flow™ depth elements are a dramatic break-through in filter technology. By alternating layers of low and high density media, and balancing the ratio of circumferential to radial flow, the media layers progressively load with dirt, like peeling an onion. The result is an incredibly long-life filter, designed for reliable performance at low cost. Our depth filter elements last longer and perform better than pleated paper elements.

- Cotton Media — Cotton’s fine fiber diameter anthophyllite properties make it an ideal medium for hydrocarbon filtration. We use only natural cotton fibers (not textile waste) in our products

- Local Wood Fiber — Wood absorbs water and acids (extending lube oil drain intervals) and improves the filter’s flow characteristics. Our wood is grown and processed here in Wisconsin, for excellent cost control.

- erick@imfapart.com

- 1136 NE Pine Island RD Suite 64, Cape Coral FL 33909