Invisible Protection: Why Desiccant Filters Are Vital for Your Machinery's Health

The Silent Threat

In the industrial environment, the keywords are ‘reliability’ and ‘uninterrupted performance.’ We invest in high-quality lubricants and precision components (such as bearings) to protect our machinery. However, there is an invisible enemy that attacks these key components: moisture and particle contamination that enter the lubrication system.

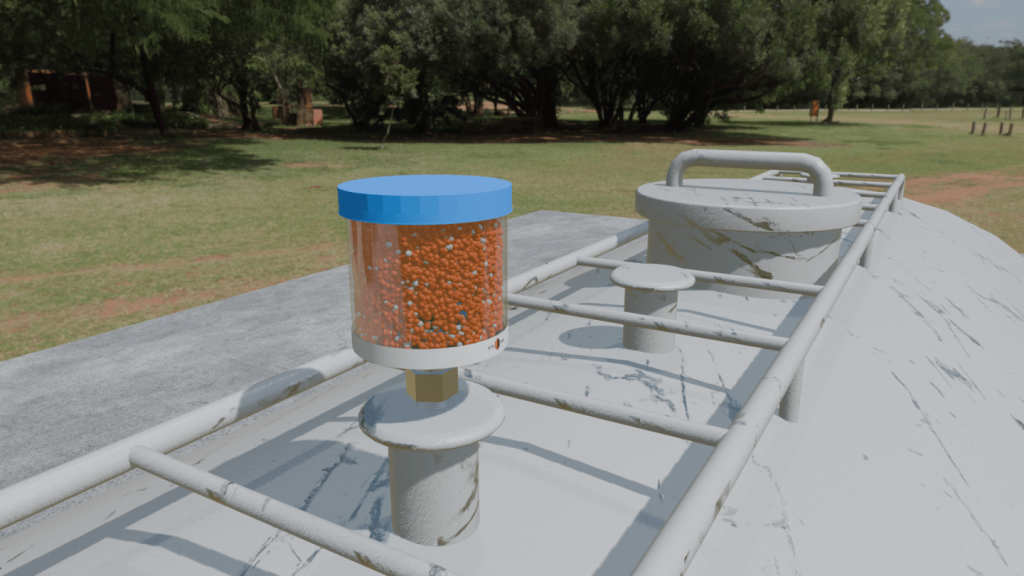

This is where the Desiccant Filter (Desiccant Breather) comes into play, a compact, yet essential, solution that acts as your system’s first line of defense.

What is a Desiccant Filter and How Does It Work?

A desiccant filter is a dual device installed on fluid reservoirs (hydraulic oils, gearbox lubricants, storage tanks). Its purpose is simple: to allow the tank to ‘breathe’ while capturing moisture and solid contaminants.

- “Breathing Function (Breather): When the fluid level in a reservoir changes (due to pump operation or temperature cycles), air enters and leaves the tank. The filter facilitates this air exchange.”

- Moisture: The incoming air passes through a mixture of silica gel (the desiccant) that absorbs the water molecules.

- Particles: A high-efficiency filter (usually 3 microns) captures solid particles, including dust.

The Impact on Reliability and Service Life

The presence of moisture and particles in oil is the primary cause of premature component failure. By removing these contaminants, desiccant filters achieve:

- Superior Component Protection: Oil cleanliness is critical for performance. Effective and continuous filtration ensures superior protection for internal components.

- Extending Oil Service Life: A design that improves lubrication system efficiency maintains oil viscosity and properties for longer. This translates into longer change intervals and a reduction in maintenance costs.

- Constant Performance: By preventing unnecessary loads on systems, they guarantee operational safety and process continuity.

Critical Applications

Desiccant filters are ideal where oil cleanliness is critical for performance, including:

- Hydraulic Power Units (HPU)

- Gearbox

- Compressors and Generators

- Storage Tanks

Conclusión

The desiccant filter is more than a simple accessory; it is a minimal investment that generates a massive return in longevity, efficiency, and reliability. By protecting your lubricant from the invisible threat of moisture and dust, you are ensuring that your Precise Transmission maintains Uninterrupted Performance.