V-Belts

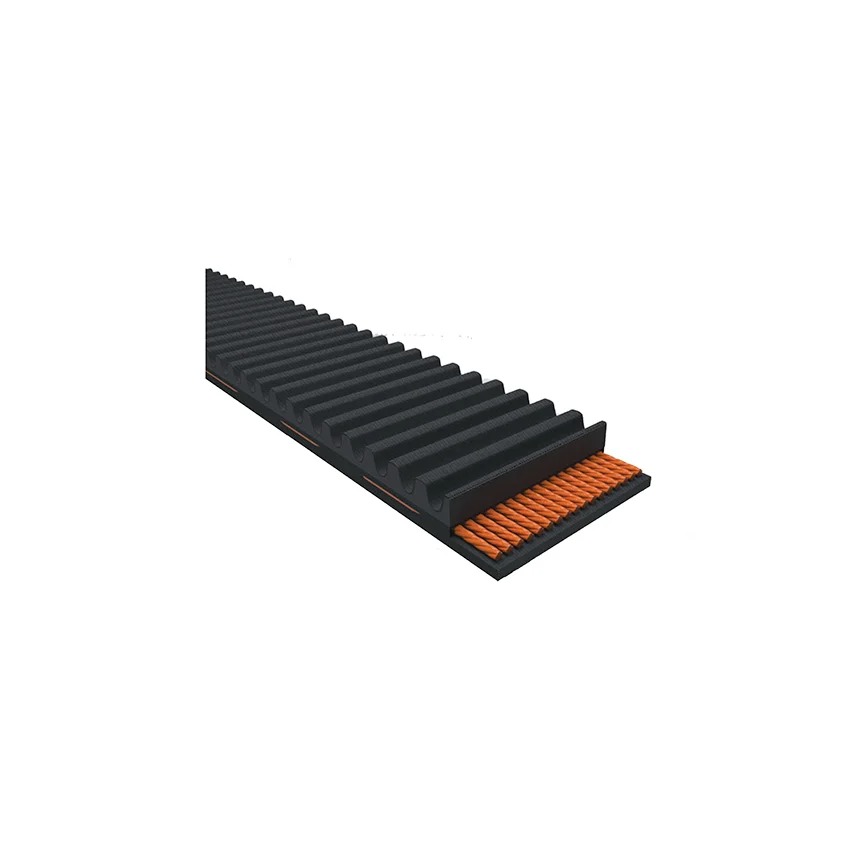

V-Belts are the most common type of industrial power transmission belt. Their trapezoidal cross-section allows them to wedge into pulley grooves, increasing friction and minimizing slippage.

They are ideal for medium to high-load applications and are widely used in pumps, compressors, fans, and industrial machinery. V-belts offer reliable performance, simple installation, and cost-effective maintenance.

Key Benefits:

-

High power transmission efficiency

-

Good shock absorption

-

Easy replacement and maintenance

-

Suitable for a wide range of industrial applications

Timing Belts

Timing belts (also known as synchronous belts) feature molded teeth that mesh precisely with pulley grooves, ensuring accurate and slip-free power transmission.

They are designed for applications requiring precise timing and synchronization between shafts, such as automated machinery, conveyors, packaging equipment, and engines.

Key Benefits:

-

No slippage

-

Precise synchronization

-

High efficiency

-

Low maintenance

-

Reduced noise compared to chain drives

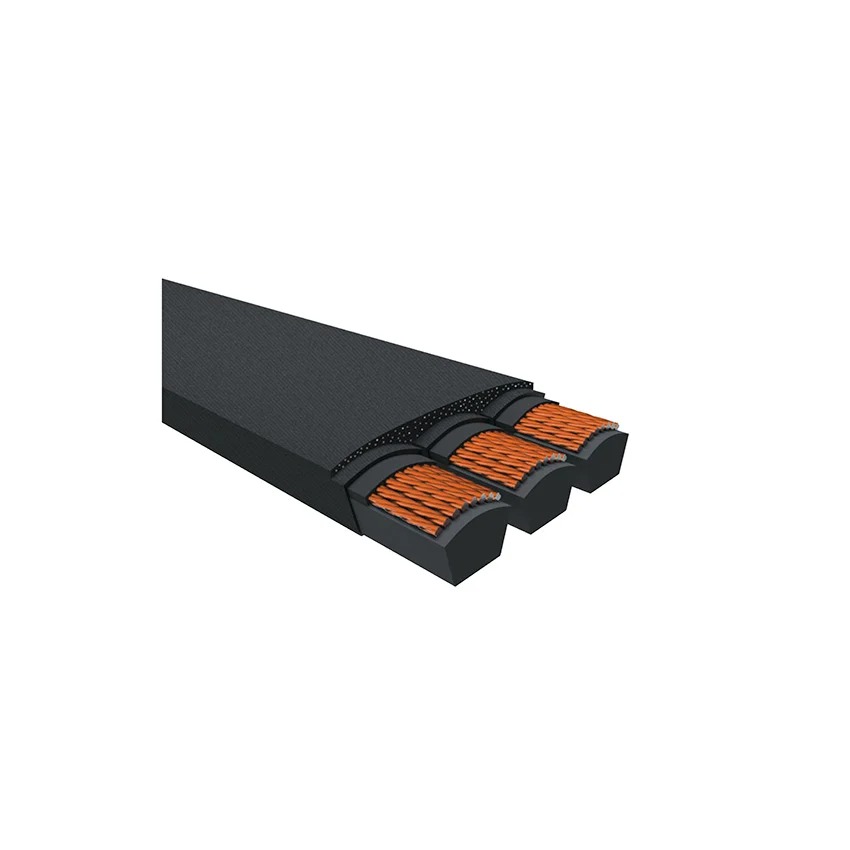

Banded V-Belts

Banded V-Belts consist of multiple V-belts joined together by a reinforced backing. This design increases stability and prevents individual belts from twisting, flipping, or jumping out of the pulley.

They are ideal for high-load, high-vibration, or shock-load applications such as crushers, heavy-duty compressors, and industrial drives.

Key Benefits:

-

Improved stability in high-vibration environments

-

Even load distribution

-

Reduced belt whip and misalignment

-

Longer service life in demanding applications