Disc Couplings

Disc couplings are high-performance, torsionally rigid couplings designed for precise torque transmission without backlash. They use flexible metallic disc packs to accommodate angular and axial misalignment while maintaining high torsional stiffness.

They are ideal for high-speed and high-precision applications such as pumps, compressors, turbines, and process equipment.

Key Benefits:

Zero backlash

High torsional rigidity

No lubrication required

Excellent performance at high speeds

Long service life

Chain Couplings

Chain couplings consist of two sprockets connected by a double-strand roller chain. They are simple, durable, and capable of handling high torque loads while allowing moderate misalignment.

Commonly used in heavy industrial machinery, conveyors, mixers, and general power transmission systems.

Key Benefits:

High torque capacity

Easy installation and maintenance

Cost-effective solution

Suitable for harsh environments

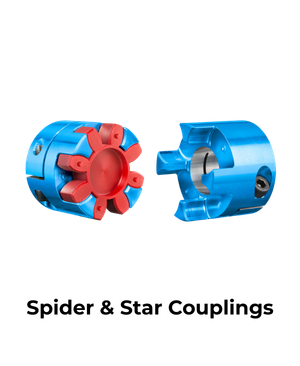

Spider & Star Couplings

Spider (jaw) and star couplings use two metal hubs and an elastomeric insert (spider/star) to transmit torque while absorbing vibration and shock loads.

They are widely used in pumps, motors, compressors, and general industrial applications where damping and flexibility are required.

Key Benefits:

Excellent vibration damping

Shock load absorption

Maintenance-friendly design

No lubrication required

Available in different elastomer hardness options

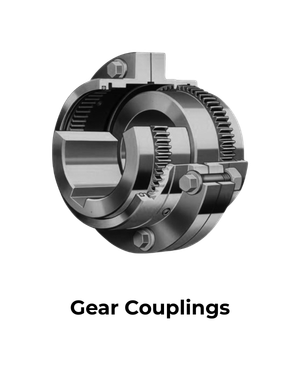

Gear Couplings

Gear couplings are designed for high torque transmission in demanding applications. They consist of two hubs with external gear teeth and a sleeve with internal teeth, allowing torque transmission while accommodating misalignment.

They are commonly used in steel mills, mining equipment, heavy-duty conveyors, and high-power industrial systems.

Key Benefits:

Very high torque capacity

Compact design for transmitted power

Accommodates angular and parallel misalignment

Suitable for heavy-duty applications