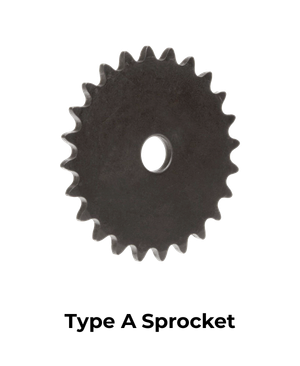

Type A Sprocket

Type A sprockets are flat plate sprockets without a hub. They are typically mounted directly onto a shaft using a hub, weld-on hub, or custom mounting solution.

Applications: Compact assemblies, custom machinery, and applications where space is limited.

Key Features:

No hub design

Lightweight and compact

Ideal for welding or custom fabrication

Type B Sprocket

Type B sprockets include a single hub on one side, providing additional support and allowing direct mounting to a shaft with keyway and set screws.

Applications: Standard industrial machinery and conveyor systems.

Key Features:

Single hub design

Better shaft support

Easy installation

Type C Sprocket

Type C sprockets feature hubs on both sides, offering maximum strength and shaft support.

Applications: Heavy-duty drives and high-load systems.

Key Features:

Double hub construction

Improved alignment stability

Suitable for high torque applications

Engineering Sprockets

Engineering sprockets are heavy-duty sprockets designed for large pitch engineering chains used in mining, cement, pulp & paper, and bulk material handling.

Key Features:

Designed for engineering class chains

High load capacity

Custom tooth profiles available

Manufactured for extreme environments

Single Sprocket

A single sprocket is designed to operate with a single strand roller chain.

Applications: Standard power transmission systems.

Key Features:

Standard configuration

Wide range of sizes and pitches

Cost-effective solution

Double Sprocket

Double sprockets are designed to operate with double-strand roller chains or two single chains running in parallel.

Applications: Higher torque requirements and synchronized drives.

Key Features:

Increased load capacity

Improved torque distribution

Ideal for heavy-duty operations

Double Pitch Sprocket

Double pitch sprockets are designed for double pitch chains, which have longer pitch spacing and are commonly used in conveyor systems.

Applications: Material handling and conveying systems.

Key Features:

Larger pitch spacing

Reduced weight

Optimized for low-speed conveying

BS Sprocket

BS sprockets are manufactured according to British Standard (BS) specifications and are compatible with BS roller chains.

Applications: Equipment requiring ISO / British Standard chain compatibility.

Key Features:

Designed to BS / ISO standards

Precise tooth geometry

Available in multiple configurations

ANSI Sprocket

ANSI sprockets are manufactured according to ANSI (American National Standards Institute) standards and are compatible with ANSI roller chains.

Applications: North American standard equipment and industrial machinery.

Key Features:

Designed to ANSI standards

Accurate pitch and tooth profile

Wide availability and interchangeability